Applications

Table of Contents

Sheet and Web Cleaners

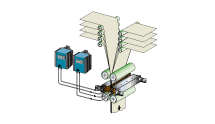

Removing particles from sheets.

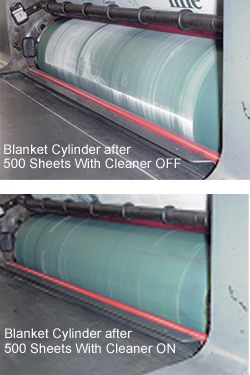

A Simco Ion-O-Vac Mark I sheet cleaner is ideal for removing dust and particulate from sheets in a sheet fed press. The Mark I can improve productivity because fewer press stops will be required to clean the blanket cylinder. The quality of printed output will also increase because hickeys, voids and crows’-feet will be greatly reduced. Finally, the work environment will be cleaner: less paper dust and reduced spray powder contamination when sheets are run through the press multiple times.

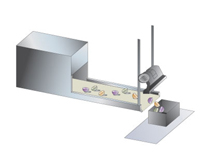

Clean web surfaces including corrugated materials

CLEANING CORRUGATED MATERIALS Slitter Dust, chaff from sheeting, and other environmental contaminants on the surface of the corrugated material make it impossible to achieve production goals and difficult to maintain quality print standards.Neutro-vac Web and Sheet Cleaning Systems effectively remove slitter dust, chaff from sheeting and other contaminants from the surface of corrugated material.

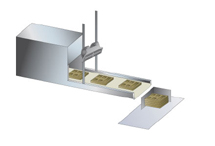

CLEANING PAPER, FILM and FOIL

Slitting, sheeting, coating, laminating, bag making, and other production processes of paper, film, and foil materials create particles that contaminate the web.

We offer a wide variety of web cleaners. The one that is right for you depends on how clean you need your web surface. Most systems are configured with static bars that neutralize static charges and prevent reattraction of contaminates to the web surface.

Air Nozzles

Selecting Ionizing Air Nozzles and Curtain Transvectors

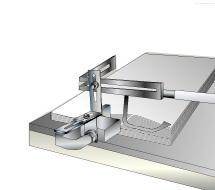

SIMCO’s ionizing air nozzles are ideal for delivering ionization into inaccessible trouble spots, such as isolated, hard-to-reach sections, dirty areas, or small spaces. Operating on compressed air, nozzles provide a highly efficient pinpoint source of ionization to neutralize charges in very specific spots, often several inches away from the nozzle tip. At the same time, dust, dirt, and particulate are blown away from the targeted surface. Available in four styles, the nozzles can be arranged in many configurations to accommodate space limitations on industrial machinery. They are available individually or optionally mounted on a standard air bar header.Simco’s ionizing curtain transvectors provide an additional alternative to static bars when a powerful “air curtain” is desired for simultaneous cleaning and neutralization. Operating on compressed air, the ionizing curtain transvector is designed to direct stream or “curtain” of ionized air at a very specific area.The forceful air curtain operates like a knife to remove dust and dirt from targeted surfaces while the ionized air prevents the reattraction of contamination.

Static problems on sheet fed presses.

A strong static charge can cause sheets on the feed pile of a sheet fed press, or other sheet fed equipment, to stick together. This can result in multiple sheet pickup and sheet registration problems leading to periodic press jams.To fix the problem, a series of R55 Ionizing Air Nozzles can be mounted around the top of the feed pile – fluffing the sheets with ionized air and removing the static charge that causes the sheets to stick together. You will have higher output and fewer headaches.

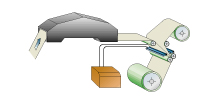

Clean with Magnum Force before painting

Use Magnum Force to clean dust and dirt from surfaces before they are painted. It is ideal for auto bodies and appliances, as shown in the accompanying photo, because air knives and air nozzles can be positioned to clean hard-to-reach places.

Conveyostat neutralizes slitter trim

Highly charged slitter trim materials cling to the sides of the cyclone of the trim collection system, forming a clog across the exit duct. The trim collection system must be shut down – affecting all operations producing slitter trim. The Conveyostat system neutralizes trim materials prior to entering the cyclone. Once neutralized, the materials flow smoothly throughout the system, eliminating system shutdown.

Slitting and rewind

Static charges can cause trim fragments and fibres to stick to films after slitting. The dirty, charged roll may cause productions slowdowns, poor product quality and even rejected product.A Phoenix Ionizing Blower installed above and after the slitting operation directs the ionization at the film and trim fragments. Static charges are eliminated during the slitting process, preventing fragments from being adhered to the film. As a result, neutralized materials stay clean and dust free, dramatically reducing slowdowns and rejected rolls, and improving overall quality.

Static Bars

Static charges on a high speed web

The PerforMAX IQ Static Neutralizing System uses a new patented technology that allows the bar to produce greater amounts of ions and project the ions greater distances than other static bar systems. The PerforMAX IQ actually senses intensity and polarity of the static charge and varies the power and polarity of the static bar to neutralize the charge quickly and effectively.In addition, the PerforMAX IQ works well in all types of applications and neutralizes even very high levels of static charges. It is particularly well suited for difficult applications where a traditional static eliminator may not be enough:* Winders or rewinders, where material is often far away from the static bar due to web path restrictions

* High speed webs — the PerforMAX IQ can handle speeds up to 2500 FPM and more

* Over open webs where it is inconvenient to locate the static bar close to the web

* In applications where the operation of the static eliminator must be closely monitored

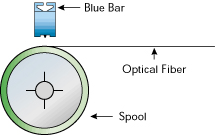

Controlling static on fibre optics

Strands of optical fibres can produce high static charges when wound onto a spool. This prevents the strands from laying properly on the spool, slowing down production. The charges can also damage the cable.Use a BlueBar to neutralize the charges from the fibres.

Static control on an open web

Static charges on an open web can attract dirt, shock operators, and cause product defects. A BlueBar will neutralize the static charges, eliminating production problems. The BlueBar neutralizes static charges on webs at speeds to 2500 FPM at 1” and can be mounted up to 6” from the web at slower speeds.

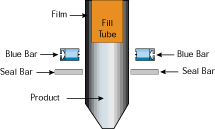

Form fill and seal

Vertical form, fill, and seal operations often result in rejects of the finished package due to product fines attracting to the film in the seal area. BlueBars positioned just below the tube neutralize the film, resulting in not attraction of fines and a clean seal.

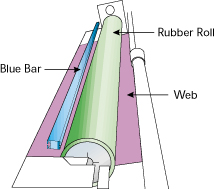

Remove static charge from a roller

In a paper mill, a rubber calendar roll was generating a 20 kV static charge. As a result, dust and debris in the air was attracted to the roll. This caused impressions from the contaminants to be transferred to the paper. An R50 Blue Bar, connected to a TrueAC Power Supply, was installed facing the roller along its entire length. The Blue Bar took the charge off the roller and helped keep contamination off the roll.

Static control in an accumulator.

Static charges can build up on a web in an accumulator. When charges become to high, the web may attract to itself or other surfaces, and the accumulator may not extend to its full range place R50 Static Bars, which are very high output bars, in the open areas between the folds of the web (see diagram). If the opposing sides of the web are within 2″ or 3″ of each other, mount the bars with the pins pointing up. This eliminates the need for two static bars within one fold. Further than 3″, two bars may be required within each fold.

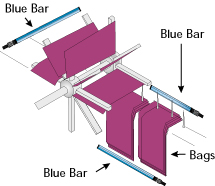

Static control on wicketer

Static charges can make bags stack poorly, decreasing production yields and increasing rejects. Because of its extended range and high ionization output, the BlueBar and PerforMAX IQ neutralize static on materials several inches away, eliminating the static charges responsible for stacking problems on the wicketer.

Static Generating

Binder or Video Cassette Cases

3-ring binders, cassette cases, and other types of binders are assembled in layers. The seal process requires that the layers stay in the position in which they were placed. Chargemaster powered PINNER bars strategically located over the assembly table allow pinning the materials together before the seal process to eliminate rejects. The various layers of the structure are held in their correct position.

Card Inserts

On perfect bound lines, card inserts often overshoot the target area because of the speed of the line. Applying a static charge to the card as it hits the page effectively holds the card in place. The card will not slide into the spine and accidental gluing will be prevented.

On the saddle stitcher, many cards can end up on the bindery floor. The problem can be practically eliminated by immediately pinning the catalog closed once the card has been inserted. A Chargemaster powered Flextac applicator placed over the signature just as they are inserted will trap the card in place preventing fall outs.

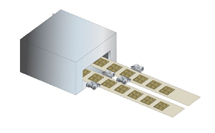

Catalog Stacking

SIMCO Chargemaster BP-30 power supply and PINNER Superbar charge catalogs just prior to stacking. As a result, the catalogs become flat and snap onto the stack, electrostatically adhering to each other. The catalogs are held together in a tight, registered stack as they proceed through the over wrapping and shrink-wrapping processes. Jams and edge damage are eliminated and throughput rate is increased. Use of strapping equipment is reduced or eliminated.

Chill – Tack

The ELTEX Chill-Tack System is designed for heat-set web offset printing presses. The Chill-Tack system uses high voltage to pin the web to the chill-roll at the first point of contact. Pinning the web to the chill-roll prevents slippage and eliminates condensation streaking. Preventing slippage also reduces tension upsets and improves registration throughout the press.

Chill Roll Edge Pinning on Cast Film Lines

A SIMCO charging applicator at each edge of the roll powered by a Chargemaster applies a static charge to the extruded film as it contacts the chill roll. The static charge effectively prevents ‘neck-in’ of the film.

Dry-Bonding Lamination

Chargemaster power supplies and charging bars work to bond the substrate and the laminating material. The materials pass between the two bars without contact and are electrostatically bonded. This ensures that materials remain aligned during the lamination process.

In-Mold Decorating

Static charges from Chargemaster can be used to pin a decorative decal tight against the inner mold surface during injection molding, a procedure which greatly improves finished product quality. A decal is placed by robot into the mold cavity. An electrostatic charge is applied simultaneously as label vacuum is turned off. The static charge pins the decal to the mold. The decal will not slip or change position in the mold.

Interleaving

Chargemaster pins the protective sheet to the base material, holding it in position through the shearing and stacking processes. Chargemaster equipment supplies the electrostatic force to bond a protective layer of paper or film to cut sheets of metal, glass, wood, and other products. Chargemaster is also used to hold wood laminates to core board prior to thermal bonding of desk tops and panels.

Plastic Bag Processing

The speed of the conveyor can cause the lead edge of the bag to lift up and shift. Electrostatically pinning trailing to leading edges prevents lifting and keeps bags proceeding smoothly along the conveyor line. Chargemaster can also be used to remove air from bags prior to packaging. The reduced thickness allows the use of smaller, more cost-efficient packaging.

Ribbon – Tacking

The Eltex Ribbon-Tacking System uses opposite polarity, high voltage DC charges to tack ribbons together. This action displaces the laminar airflow between ribbons and the ribbons gain strength from the intense but temporary static charge. The ribbons are now easily moved through to finishing with ‘dog-ears’ and creases prevented.

Roll-to-Roll Changeover

Chargemaster applies a temporary charge to the leading edge of the roll of film at rewind. The edge then adheres to the core without the use of tape or messy adhesives. Finished product quality is enhanced by elimination of creases in the roll of film caused by tape and glue on the core.

Shrink Wrapping

An electrostatic bond holds sheets of paper or plastic in place until the heat sealing or welding is completed.Chargemaster applies an electrostatic charge to bond sheets together to keep them in a tight stack. This prevents the film over wrap from pushing the top sheet out creating a shingling problem. Imperfect packaging and damaged sheets are also prevented.

Static Blowers

Injection molding

Injection molded parts can have high static charges which attract airborne contamination, resulting in product rejects. Operators may also experience uncomfortable shocks working next to the collection bin,The Phoenix Blower provides ionization to quickly neutralize the molded parts. As a result, the parts no longer attract airborne contaminant and remain clean while operator shocks are eliminated.

Cleaning thermoformed trays

Thermoformed trays attract dirt and contamination resulting in rejects.The Phoenix Ionizing Blower installed directly above the delivery of the thermoformed trays offers improved product quality with the reduction of dust and dirt.

Plastic parts

Plastic parts can have high static charges and can attract dust and dirt, resulting in rejected parts.The Phoenix Blower installed on a belt conveyor and directed at the plastic parts will neutralize the static charges, prevent attraction of contaminants, and reduce rejects.